Thermal Printing

What are Thermal Printed Labels?

Thermal printing is a type of printing process that uses heat, hence the “thermal” in its name. This technology is flexible, low maintenance, cost-effective, and creates durable, high-quality images. Thermal print technology can be found everywhere. Ever watched a receipt print at a grocery store? That’s thermal printing in action. This printing technique is applicable to a wide range of industries and can accommodate simple print runs, like price tags, to more complex operations, like nutrition facts labels, QR codes and barcodes, and more.

Theremal Direct Printing

There are two types of thermal printing. The first is thermal direct printing. This is a printing process that uses a label substrate (or label material) treated with a thermochromic coating, or a heat-sensitive coating. The thermal printer has a heated print head, which passes over the substrate, introducing heat to its surface. The substrate will change color where the heating elements in the print head touch its surface, producing an image.

The second form of thermal printing is thermal transfer printing. This process is quite like thermal direct but instead of utilizing a label substrate with thermochromic coating, thermal transfer printing uses a regular label substrate with a heat-sensitive ribbon. It works similarly to thermal direct printing, using a heated print head. However, in this process, the heat-sensitive ribbon transfers ink to the substrate to produce an image.

Thermal transfer Printing

Shop Thermal Printed Labels in the Derksen Co. Store

Thermal Print Benefits

No matter which thermal print method you pick, thermal printing has some large benefits.

Media Flexibility

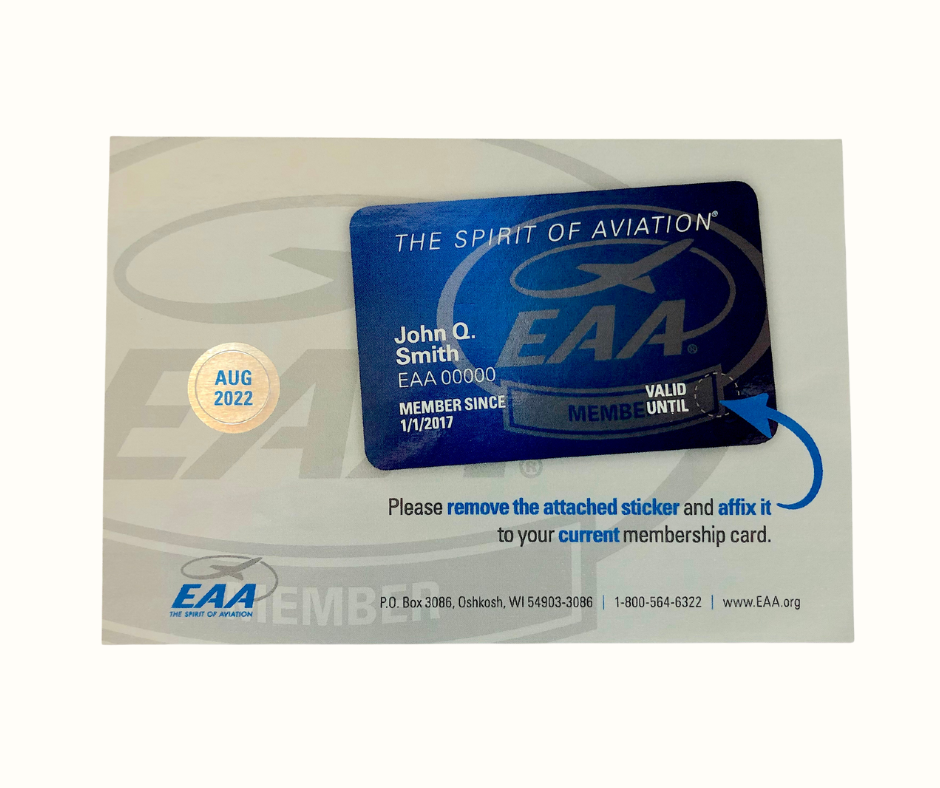

Thermal printing has a wide range of applications and a great variety of printing possibilities. It can be implemented with varying substrates, materials, and uses from barcodes, to nutrition facts labels, to ID cards, tags, and more.

Durability & Sustainability

Thermal printing produces durable results, suitable for a number of industries and uses. It is also a sustainable option for businesses looking to get the most out of their printing equipment, being a long-term, consistent printing solution.

Flexibility

Thermal printing is easy to implement and easy to change according to your business’s needs. Amending label information is simple and design changes can be achieved seamlessly, allowing you to keep your products up to date.

Contact Us

Thermal printed labels are a great solution for all types of product packaging needs. Contact us at Derksen Co. to find out more about this label technology and to see how you can implement thermal labels into your branding strategy.

Thermal Transfer vs. Thermal Direct

When choosing a thermal printing method, you’ll want to determine the needs of your business, your application uses, and the cost of each option. Thermal direct printing can be more cost-effective because it doesn’t require ribbon stock or the technological capabilities necessary for ribbon functionality. It can also be more efficient because there is no time spent replacing the ribbon during print runs. However, its substrate options are limited to paper and polyester and you may end up replacing your print head more frequently than with thermal transfer due to increased friction during the printing process. Thermal direct printing can also be more vulnerable to environmental factors that may compromise the label design. For example, extended exposure to ultraviolet light can grey and deteriorate thermal direct printed materials. If your label doesn’t require a longer lifecycle or come into contact with abrasive elements, thermal direct can be a great option for its high resolution.

Thermal transfer printing allows you to work on more substrates than thermal direct and more colors due to its incorporation of a heat transfer ribbon rather than a heat activated substrate. The cost of thermal transfer may be higher up front, but it pays off if your printing needs are more versatile or you want to incorporate more intricate designs, multiple colors, or variable information. You also won’t replace the print head as frequently because of the wear and tear protection of the ribbon. Thermal transfer printing, like its counterpart, produces high resolution images and gives a bit more durability for applications where exposure or external stressors are involved in the label’s lifecycle. A large benefit of thermal transfer printing is its ability to be combined with other print technologies and highly diverse substrates. You can combine thermal printing with printed flexo or digitally produced label stock, as well as print on an exceedingly wide range of materials from paper to textiles.

How can Thermal Printing be Used?

-

Serial Numbering

Thermal printing can be optimized to produce serial numbering, meaning it can create a unique identifier which can be assigned sequentially, allowing you to uniquely identify items. This technology is commonly used in the medical industry for patient identification, in logistical operations, and more.

-

QR Codes

Thermal printing can be integrated with smart tech like QR codes to create interactive content. Common applications include the restaurant industry’s integration of menu-linked labels, website-linked branding in the retail industry, resource or instruction-linked labels on products, and more.

-

Barcoding

One of the most common uses of thermal printing is the creation of barcodes. Thermal printers can be easily connected to barcode generation software, letting you easily build and print your own auto identification tools. Common applications include retail operations, tracking, shipping, storage, and more.

-

RFID Encoding

Thermal printers can be combined with RFID encoding software. As an RFID-enabled substrate passes through the printer, its data can be encoded while its surface is imprinted with an image, saving time and simplifying the RFID labeling process. RFID printing and encoding is commonly implemented in retail, logistical, security operations, and more.